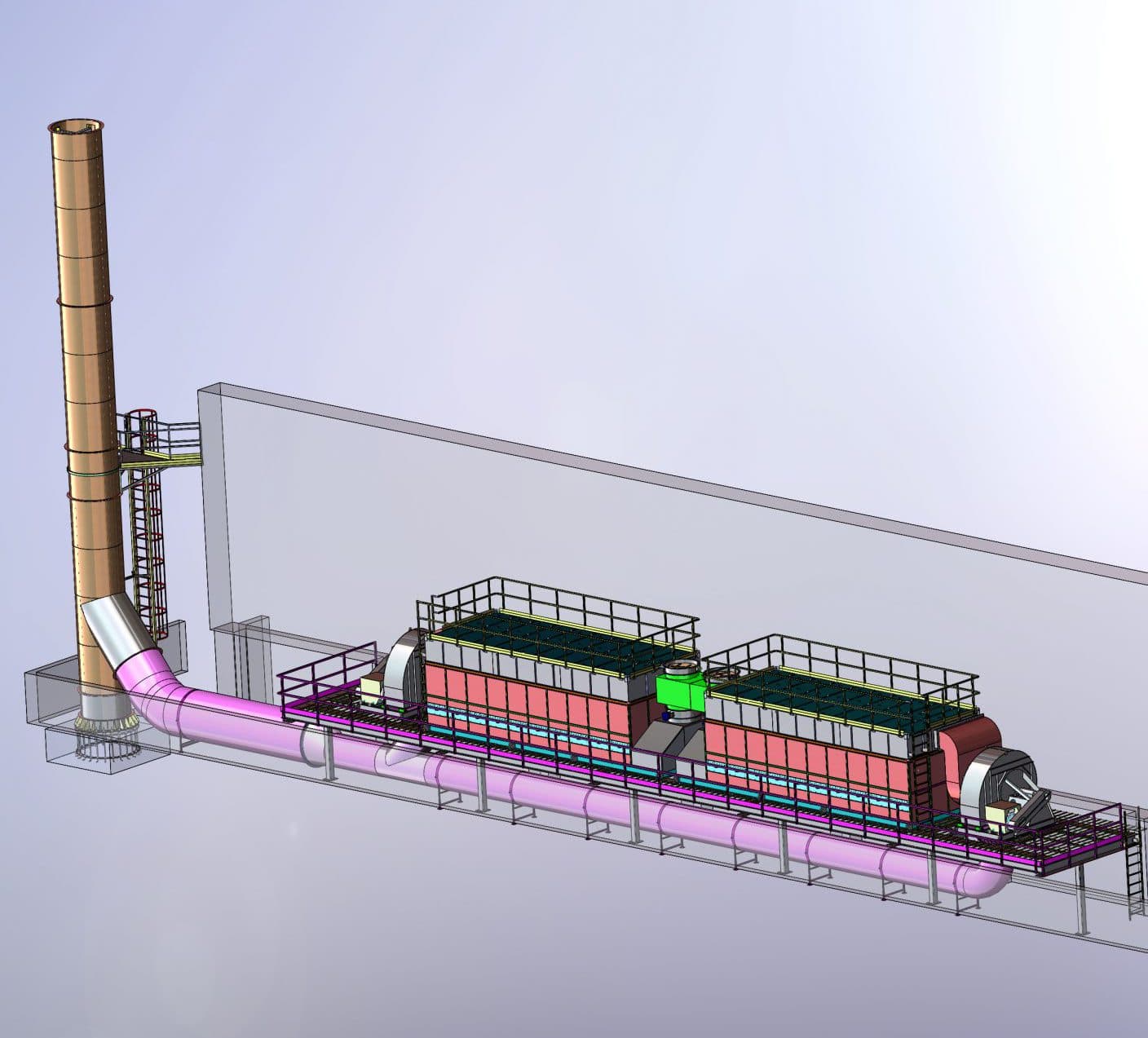

Acid vapor and halogen treatment system from VOC combustion process in the pharma industry

ABP Chemical Engineering and Ventilation Engineering Ltd. specializes in the design and installation of systems for the treatment of emissions of acid fumes and halogen vapor. Our company has designed and installed numerous systems that meet the most strict environmental standards.

A large Pharmaceutical manufacturing company has received a request from the Ministry of the Environmental protection to install a system for the treatment of acid fumes and halogens produced in one of the thermal oxidizers facilities at the plant.

The project prevented 100% of pollutant emissions and achieved compliance with all the strict standards of the Ministry of Environmentalal protection, and specific standards that applies to the pharmaceutical industry.

The system consisted of two stages: a gas quencher and a packed bed scrubber with high efficiency droplet separator for treating acid fumes and halogens with Caustic solution and SBS. The system was designed to reduce reagents and water consumption costs.

- Pre- treatment - cooling the gas stream with Gas Quencher.

- Main treatment – packed bed scrubber for neutralizing acid fumes and halogens.

- High efficiency mist eliminator to prevent pollutant reentrainment to the clean gas stream.

- Hot Bypass - To prevent damage to the scrubber system in the event of a fault in the gas burning process in the RTO.

- Preparation of PFD and P&ID flows sheets.

- Continuous CEMS monitoring system in accordance with strict requirements of the Ministry of the Environmental protection.

- Spark protected blower suitable for the flow and pressure drop thinking of the entire system.