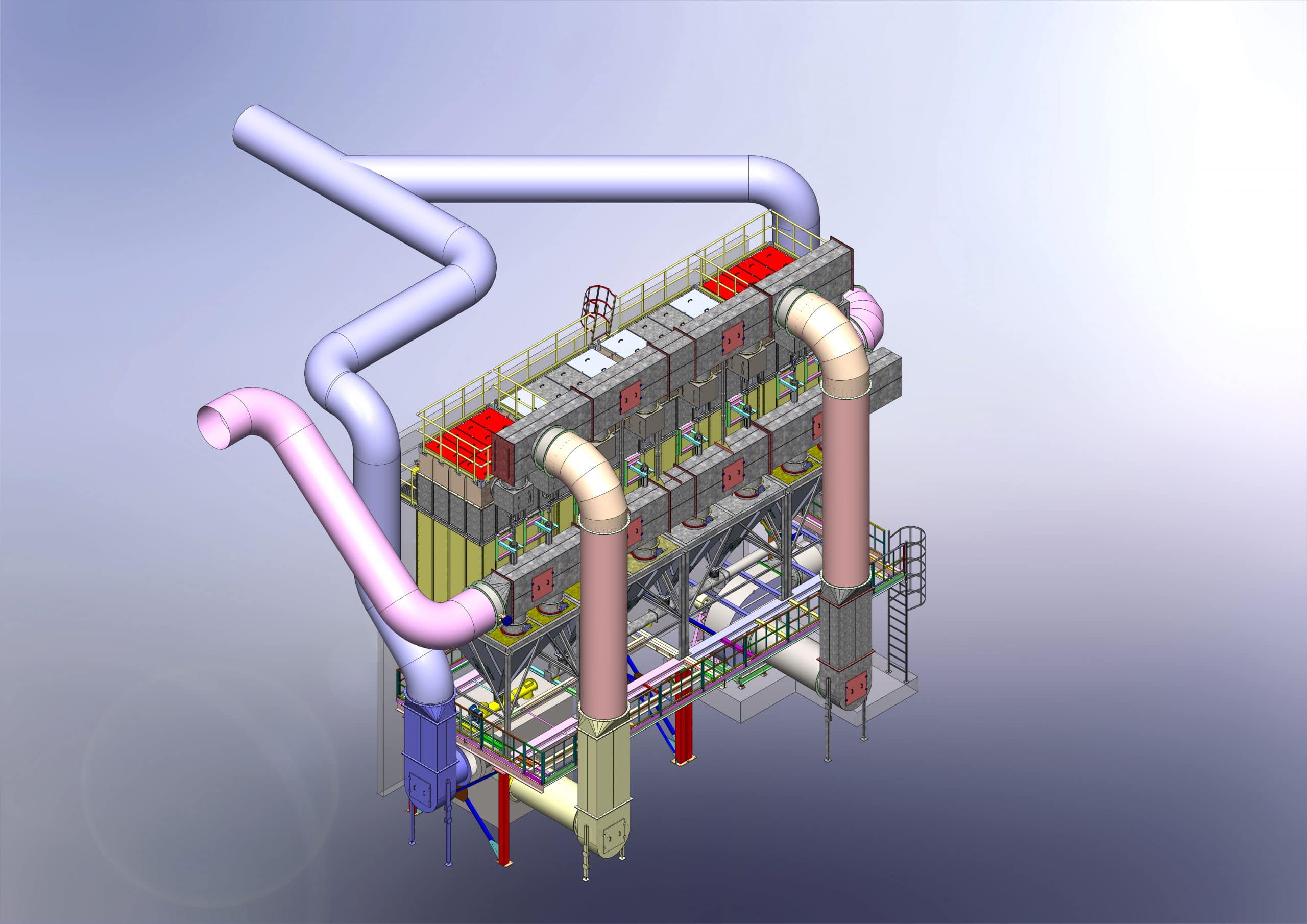

Dust extraction collection and prevention system in the metal smelting industry

A large manufacturing plant in the metal industry has received a request from the Ministry of the Environment to treat dust emissions from rotary kiln smelting processes.

ABP Chemical Engineering and Ventilation Ltd. Designed & installed a treatment system to meet both plant requirements and regulatory requirements.

The treatment system was built from 2 parallel dust collection units. The units communicated by means of control system to reduce operating costs and to comply with the maneuverability required by the plant in terms of operating production lines and preventing air pollution.

- Assembly and design of dust extraction hoods from: Rotary clean and other process equipment.

- Design and installation of dust collection system. With required valves and control equipment for maneuverability.

- Design and installation of dust treatment systems consisting of 2 parallel treatment units. With the required unique control system.

- Implementation of the control system in the factory existing HMI main control room.

- Supply and installation of 2 dedicated new blowers. Connecting the treatment exhaust to an existing chimney.