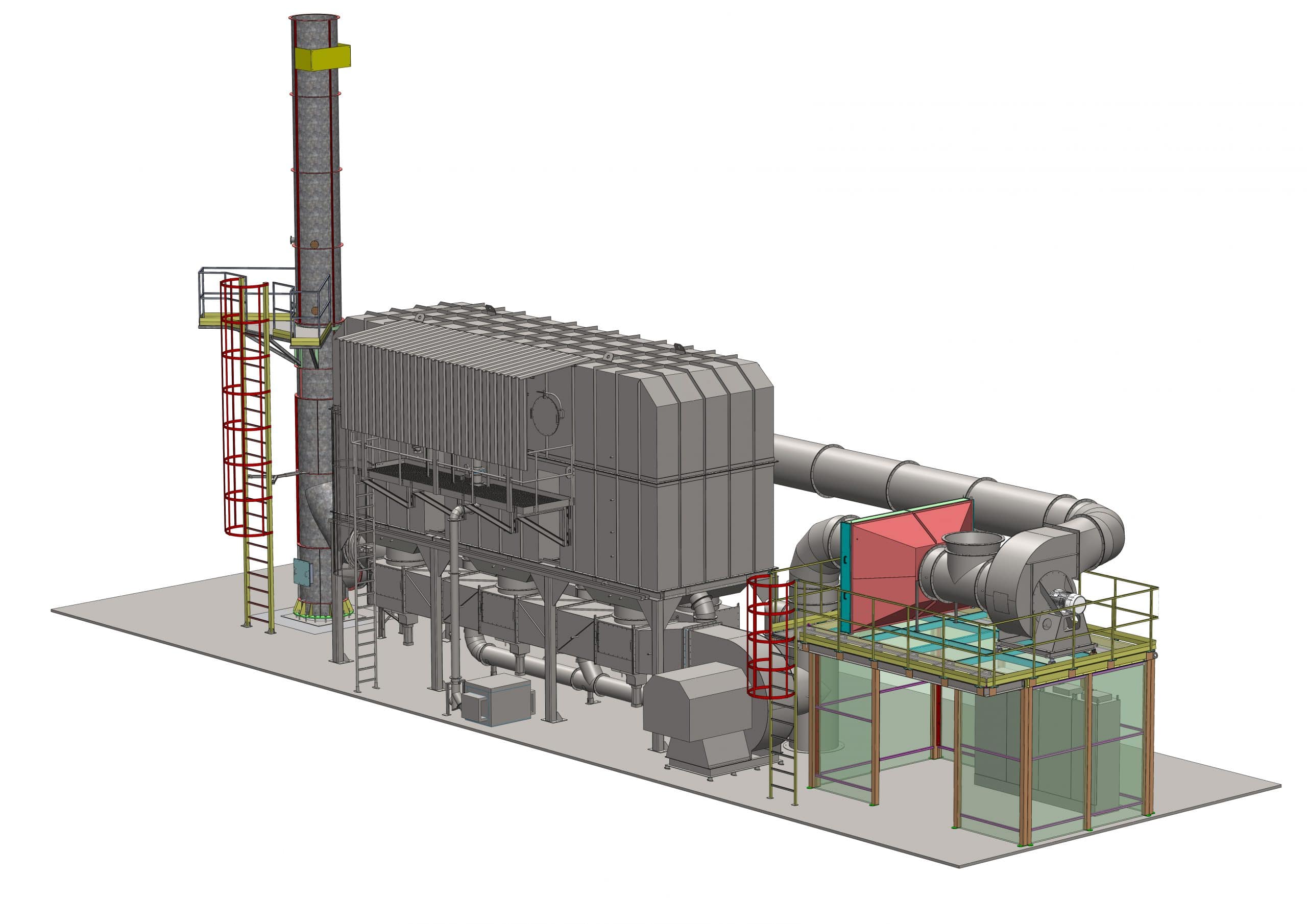

RTO system for the treatment of VOC emissions from solvents in the Food Industry - Retrofitted system.

ABP Chemical Engineering and Ventilation Ltd. specializes in the design and installation of RTO treatment systems for VOC emissions treatment In the food industry.

A large food manufacturing plant has received a request from the Ministry of the Environmental protection prevent and treat VOC emissions from production processes.

The budget for a project that the plant could put in place was limited and the plant could not purchase a new RTO system. ABP Chemical Engineering and Ventilation Ltd. used the networking circles in Israel and abroad for the purpose of locating a second hand RTO system, which could significantly reduce the cost of the project without making any compromises to the required system performance.

The project prevented emission of 100% of pollutant emissions and achieved compliance with all the required standards of the Ministry of the Environmental protection and specific standards of the food industry.

- 99.8% VOC destruction efficiency.

- 96% heat recovery efficiency.

- Collecting and preventing 100% VOC emissions in the plant environment.

- Significant reduction in operating costs (OPEX) for operating a treatment system.

- Completing the project within its budgetary limits.

- Refurbishing of all second-hand RTO equipment. Including shoot blast, new epoxy paint, replacing gaskets, renewed gas train, renewed and upgraded gas burners etc.

- Installation of a new fan with VFD drive and control system.

- Integrating and designing the new control protocols in the plants existing HMI system.