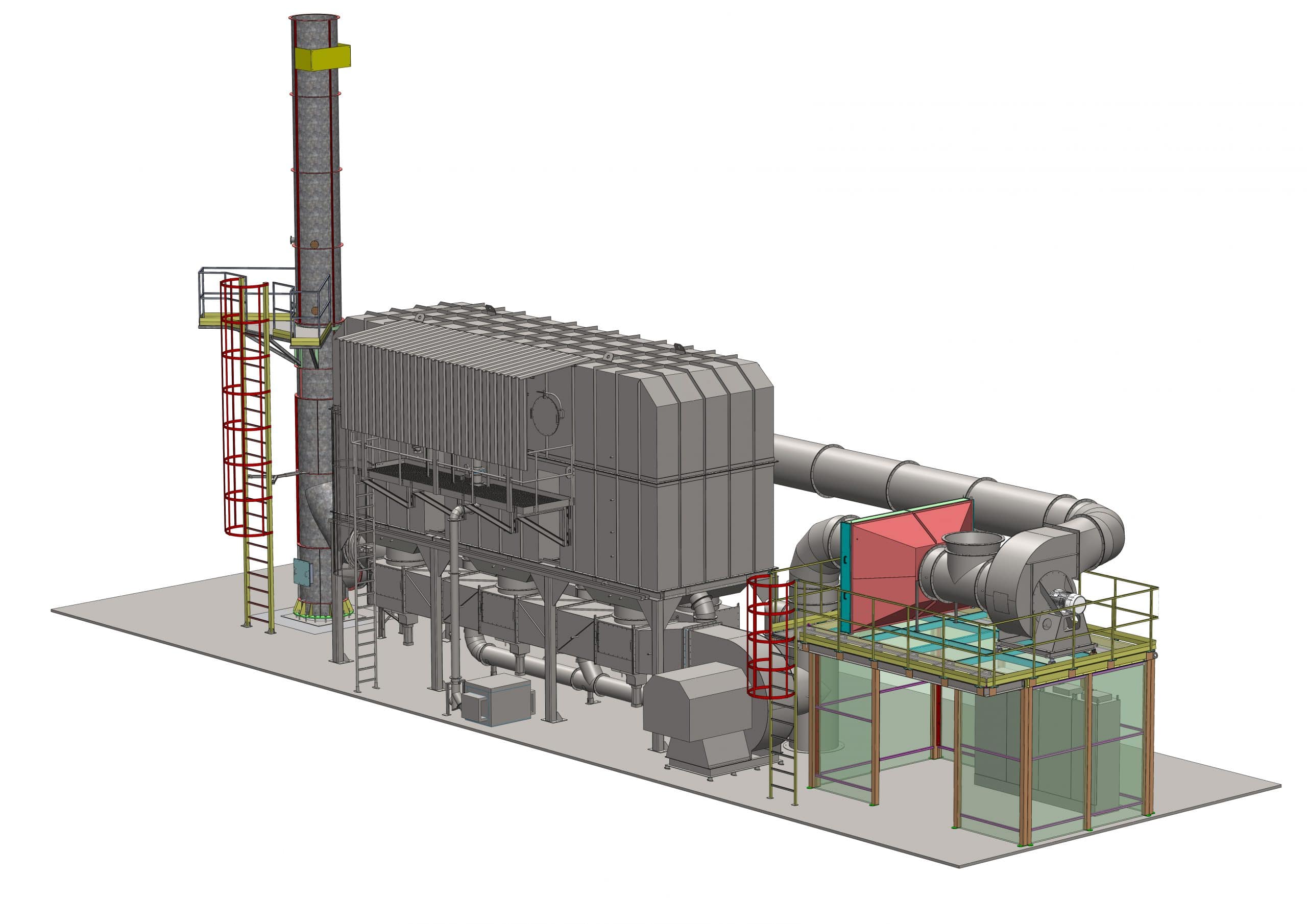

RTO system for the treatment of VOC in the cosmetics industry & Reducing fuel costs.

ABP Chemical Engineering and Ventilation Ltd. specializes in the design and installation of RTO thermal treatment systems for VOC emissions treatment. ABP Chemical Engineering and Ventilation Ltd. is recognized as a leader in Israel in the field of thermal oxidation systems for VOC treatment.

A large Israeli cosmetic products manufacturer has received a request from the Ministry of the Environmental protection to treat and prevent VOC emissions from his manufacturing processes.

The plant engineering department contacted ABP Chemical Engineering and Ventilation Ltd. And we started with the design of the most cost effective solution to be implemented in the plant.

The project prevented 100% of pollutant emissions and achieved compliance with all the required regulation standards of the Ministry of the Environmental protection (Israel adopted the TA LUFT 2002 Standards) for the specific needs of the cosmetic industry.

The RTO system was designed to reduce fuel consumption costs for burning pollutants and in fact works without supplying fuel more than 80 percent of the time due to the energy content in the waste gas.

- Pre-treatment - Cartridge filter to prevent dust from entering the RTO system and preventing clogging, corrosion and future malfunctions. For dusty streams.

- Pre-treatment - dedicated cyclonic droplet separator to prevent large drops from entering the RTO system. For heavy vapor streams.

- Pre-treatment - Pre-heating of the gas stream by a series of heat exchangers to prevent condensation and improve RTO work.

- LEL control system - to prevent explosion hazard and control the concentration of pollutants at the entrance to the system.

- Hot Bypass - Prevents the RTO system from stopping due to system overheating. This prevented the RTO system form experiencing outages.

- Preparation of PFD and P&ID flows.

- Continuous CEMS monitoring system in accordance with the requirements of the Ministry of the Environmental protection.

- Installation and design of collection duct layout system that includes connecting units of equipment and performing suction with the help of designated innovative Hoods.

- Spark protected blower suitable for the flow and pressure drop calculated for the gas conveying and treatment system.

- Standard chimney in accordance with the requirements of the CEMS system installation.