Cost effective solution Retrofitting R.T.O.

RTO systems are industry standards for treating and destroying organic and odorous pollutants and are defined as Best Available Technology (BAT) for treating VOC.

A factory producing food products received a demand from the Ministry of Environmental protection to begin testing for organic pollutants in chimneys that had no expectancies of having any presence of organic pollutants. The tests showed a significant presence of organic pollutants requiring treatment before emission to the atmosphere.

The factory reached out to ABP Chemical and Ventilation Ltd. and gave it the test results. The company’s engineers reviewed the data, made tours of the factory, and found the necessary system required to meet the Ministry’s standards is an RTO thermal oxidizing system.

Oxidation of organic materials is a process where organically polluted air is filtered through a system with a high-temperature combustion cell. The high temperature in the cell incites a reaction between the organic pollutant with the oxygen in the air called Combustion. The products of the said reaction are CO2 (Carbon Dioxide) and water, both considered harmless and can be released into the atmosphere.

With a limited budget for the project, the factory could not afford a new RTO system. ABP Chemical and Ventilation Ltd. used its broad knowledge and connection with industries both inland and abroad to locate a second-hand RTO system, which significantly lowered the cost of the project.

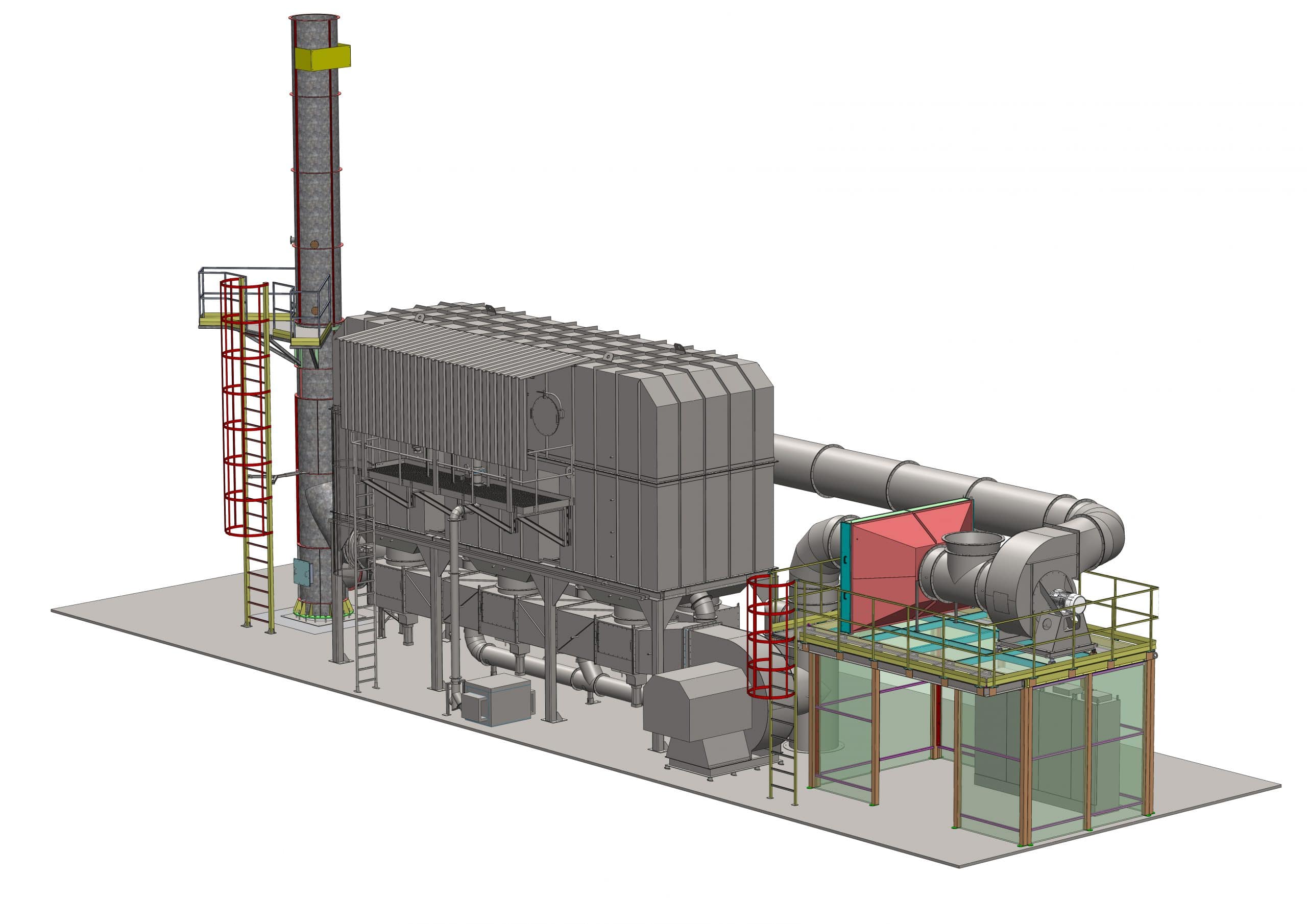

A compatible second-hand RTO system was located in a factory in Israel. The system was shut down due to production volume growth and the purchase of a larger system. ABP Chemical and Ventilation Ltd. began a complicated logistic operation designed to dismantle the RTO system on the factory grounds and deliver it to the client. The purchased system was left unused for several years and required extensive renovations to reconstruct it to an applicable shape.

Some of the renovative actions for the system were:

- Insulating the system.

- Sand-cleaning system’s interior.

- Painting the system’s exterior.

- Replacing malfunctioned pistons, activators, and status indicators.

- Integrating a new VFD on the system’s main bellow.

- Replacing the ceramic filling.

- Installing a new Gas Train.

- Upgrading the torches.

- Upgrading the system’s overall safety array, adding analyzers at the entrance to the system to read the organic material concentration and prevent explosions.

- Renovating the system’s control room.

- Adding a new control and operation HMI screen.

- Integrating the RTO’s monitoring system to the factory’s monitoring system, including a sequence of actions requested explicitly by the client.

Parallel to the renovation process, ABP Chemical and Ventilation Ltd. began setting up a new emission collection array designed to route the gas, which previously went straight to the chimneys, to the newly installed RTO system. The collection array included over 500 meters of pipes collecting gasses from 10 different emission sources. Also, in order to reduce the amount of gas entering the system, the collection layout was designed with disconnecting inactive collection sources, thus lowering the airflow, increasing the treatment effectiveness while lowering the system’s gas and electricity costs. In addition, an array of filters and air dryers were placed at the entrances to the collection system in order to increase energy efficiency, prevent obstructions, and increase the longevity of the system.

ABP Chemical and Ventilation Ltd. engineers stayed in continuous touch with the factory during all stages of the project and delivered solutions for any subject that came up during or after the project.

After testing the new chimney, the plant met the necessary values set in the emission permits by the Ministry of Environmental protection; the emission levels tested were lower than those set for the factory. 10 mg/m3 per half hour average.