How do absorption systems and regenerative thermal oxidizers interact?

Regenerative thermal oxidizers are an industry standard for treating and destroying organic and odorous pollutants.

Oxidation of organic materials is a process where organically polluted air is filtered through a system with a high-temperature combustion cell. The high temperature in the cell incites a combustion reaction between the organic pollutant with the oxygen in the air. The products of this reaction are CO2 (Carbon Dioxide) and water, both considered harmless and can be released into the atmosphere.

But what happens when organic compounds containing Chlorine,Bromine or other halogen elements or molecules enter the Oxidizing system?

A Regenerative thermal system worked regularly and without problems at a factory in southern Israel. After some time, corrosion was visible on the RTO system’s chimney. An inspection conducted by the factory found substantial irregularities in HCl acid and Cl2 (Chlorine) emissions. An inquiry conducted by the factory discovered that the emission of organic compounds containing chlorine molecules (Cl) began as a result of changes made to the production process. When organic halogenated (with chlorine) compounds reach the RTO system, they burn and create HCl acids and Cl2 gas in addition to carbon dioxide and water.

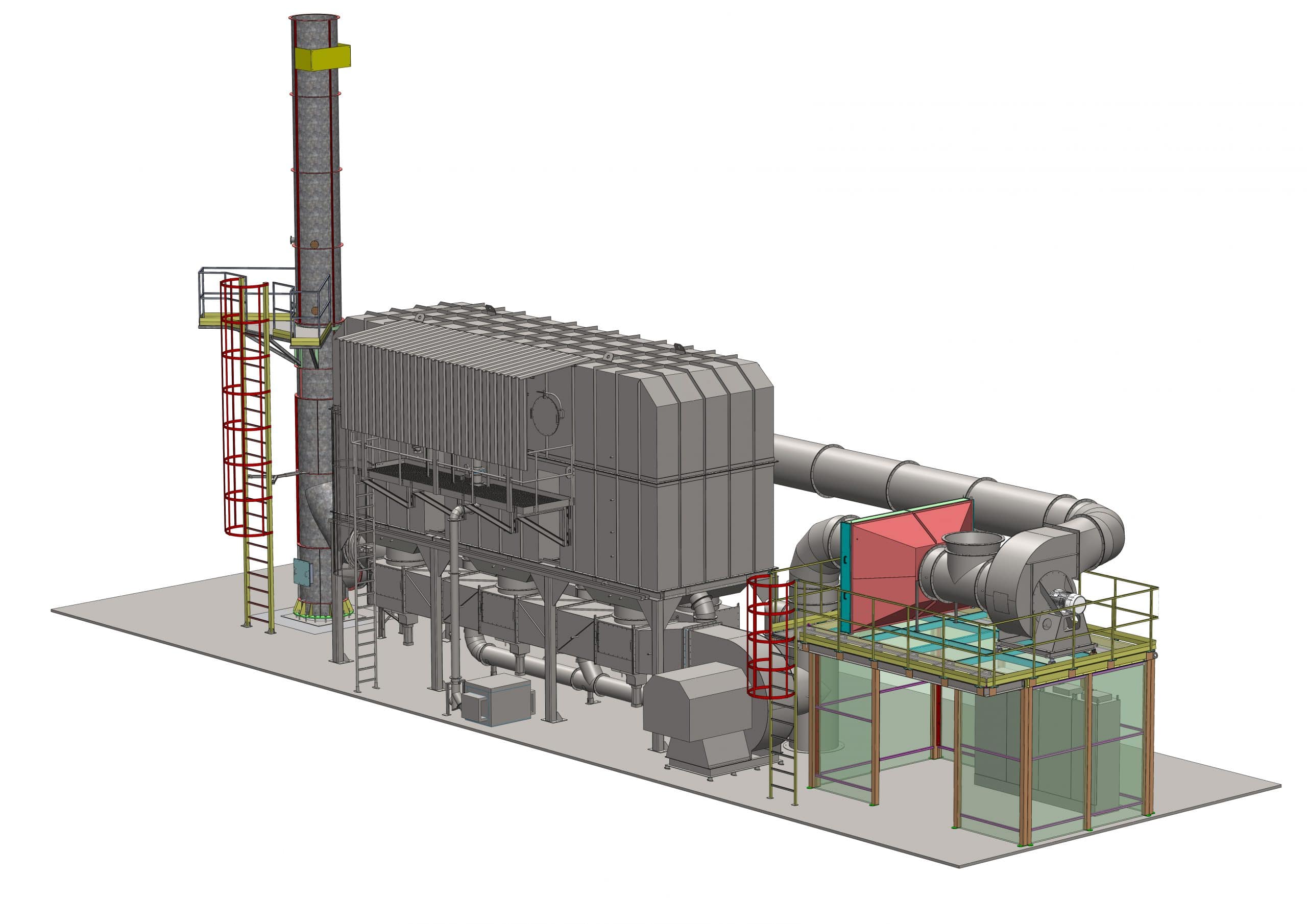

ABP Chemical and Ventilation Ltd. offered the plant an encompassing solution to the HCl and Cl2 gases by adding a two-stage system.

Stage One – Quencher:

In order to treat the hot gasses leaving the RTO system and effectively treat and guard the structural compounds of the treating system, they must first be cooled. ABP Chemical and Ventilation Ltd. designed a quencher column with two parts, which sprays water at the incoming gasses in order to cool them.

Stage Two – Absorption column:

In order to treat the HCl gas and Cl2 gas emitting from the RTO system, ABP Chemical and Ventilation Ltd. designed and installed an alkaline packed bed absorption system which promotes the transition of pollutants from gas phase to liquid phase, where the acid is neutralized by the alkaline agent. The treated gasses moving through the absorption column are then released to the atmosphere via a chimney located on top of the absorption column with the fan preceding the absorption system.

After installing and test-running the system, several emission surveys were ordered to evaluate and check the system’s performance. These surveys found that the emission values meet the necessary values required in the emission permits by the Ministry of Environmental protection.