Surveyers fill

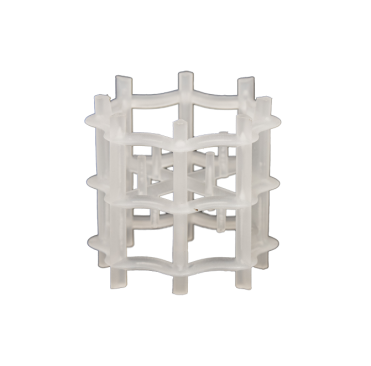

Random filling is an essential component of mass transit applications such as absorption, distillation and stripping. The main function of the filler is to increase the contact area between gas and liquid and thereby promote mass transfer between the phases.

The filler comes in a variety of shapes and sizes that differ from each other in the mass transit elevator, at the pressure drop that the filler creates in the column and the cost of money. By rule of thumb you can say that the higher the filling and the lower the pressure, the lower the efficiency.

If filling time decreases due to filling distortions caused by: the weight placed on the filling, the gas and liquid temperature and the foiling resulting from particles entering the system, chemical reaction or biofouling. As a result, it is recommended to renew and replace the refill once every two years.

ABP Chemical and Ventilation Engineering Ltd. markets a variety of random fillers to columns, and with the help of its engineers is able to offer the fill with the best cost / benefit ratio for the required application.

- Raschig Ring

- Pall Ring

- Saddle Ring

- High performance packing

- Metal (CS, SS304/316, Nickel, Aluminium, Copper, Titanium, Zirconium

- Plastic (PP, PVC, PVDF, PTFE)

- Ceramics